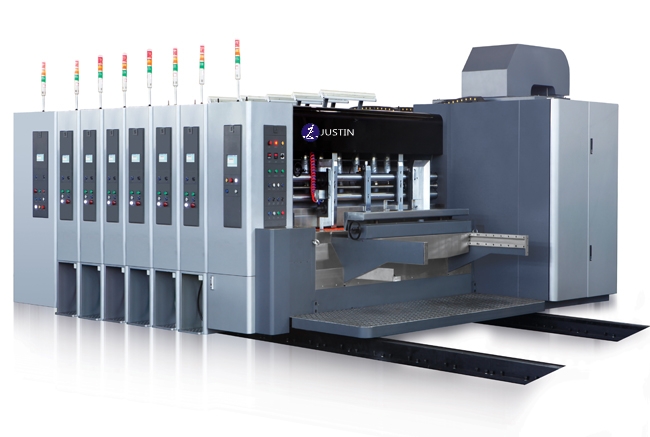

YKC-Machine features

YKC machine is a classic flexo printer slotter die-cutter, which reflects state-of-art design and is very practical. It is designed for high performance, reliability, operator’s safety and user-friendly controls to produce top quality cartons.Vacuum transfer ST Flexo printer slotter is available.

WHOLE MACHINE INTRODUCTION

The machine is controlled by PLC and the phase is regulated by frequency converter.

Servo drives lead edge feeder to get more precise and more stable feeding.

Servo drives Compensation system to get more quite precise die cutting carton.

Being able to store 9999 orders.

Automatic washing device can save inks effectively (0.3~0.5kg each time at each printer).

Driving gears adopt 20CrMnTi alloy steel. The gears are heated especially and then precisely grinded and reach 6 grade precision and HRC 58-62 degree.

All drives shafts are made of high-quality steel, chrome plated, and surface ground.

Pulling feed roller with self-locking and quick adjusting function has easy operation and can avoid damaging roller.

Adopting free loop bound to reduce abrasion and print accurately.

All units of the machine can be separated automatically or manually and an audible alarm sounds during the opening and closing for safe operation.

Gap adjust adopts self-lock adjusting device,and it is easy for operation.

The lubricating system adopts spraying anti-squirt device and automatic circulating lubrication with anti-leakage oil mechanism.

Main Specifications:

|

Model |

YKC-1000 |

YKC-1200 |

YKC-1400 |

YKC-1600 |

||||||

|

1800 |

2200 |

2500 |

2800 |

2500 |

2800 |

2500 |

2800 |

|||

|

Max. feeding size(mm) |

1760*970 |

2160*970 |

2500*1170 |

2800*1170 |

2500*1370 |

2800*1370 |

2500*1570 |

2800*1570 |

||

|

Min. feeding size(mm) |

650*280 |

650*280 |

650*350 |

650*350 |

650*380 |

650*380 |

700*400 |

700*400 |

||

|

Skipping feeding(mm) |

1760*1170 |

2160*1170 |

2500*1370 |

2800*1370 |

2500*1570 |

2800*1570 |

2500*1770 |

2800*1770 |

||

|

Max.printing area(mm) |

1750*950 |

2150*950 |

2450*1150 |

2750*1150 |

2450*1350 |

2750*1350 |

2450*1550 |

2750*1550 |

||

|

Standard printing plate thickness(mm) |

7.2 |

7.2 |

7.2 |

7.2 |

||||||

|

Min.slotting space(mm) |

Normal | 120*120*120*120 | 140*140*140*140 | 150*150*150*150 | 150*150*150*150 | |||||

|

Reverse |

190*50*190*50 |

250*80*250*80 |

250*80*250*80 |

250*80*250*80 |

||||||

| Effective feeding range(mm) |

2.5-10 |

2.5-10 |

2.5-10 |

2.5-10 |

||||||

|

Max. slotting depth(mm) |

300 |

300 |

350 |

350 |

350 |

350 |

350 |

350 |

||

|

Max. speed(sheet/min) |

200 |

200 |

170 |

170 |

150 |

150 |

130 |

130 |

||

WIKE-TP-Die-cutter Unit

ROTARY DIE-CUTTER

Die-cutter phase, can be controlled on the main console or each unit console.

Pneumatic gear gap locking device, gap motorized setting and adjusting.

Rubber anvil roller automatic displacement mechanism, prolong the service life of anvil.

Quick replacement rubber anvil is imported from USA CUE., it is easy for replacement and wear- proof.

Rubber anvil regrinding mechanism which prolongs its utilization rate and reduces consume.

Precision “control type” speed differential compensation system, ensuring die-cutting precision, wide compensation range.

WIKE-TP-Dryness Section

DRYNESS SECTION

It can be controlled on the main console or each unit console.

Vacuum transfer, air volume is adjustable, ensure it stable transfer.

Vacuum transfer box synchronized lifting, gap motorized setting and adjusting.

Hot air drying model, thermo regulation adjustable.

Blower and hot air for option, to fit different production.

Option- infrared ray or UV dryers mode.

WIKE-TP-Slotter Unit

SLOTTER

Slotting phase can be controlled on the main console panel or each unit console panel.

Motorized set up all box dimension.

Robust yoked creaser and slotter heads.

Cardboard box high slotting use inside-gear device, driving gear box synchronized adjust.

Precise straight line rail with cross linkage shaft system so as to achieve accurate lateral movement with glabrous slotting.

Middle knife long distance moving mechanism with edge slitting device to adapt to flexible production.

Spring type single slitting knife with glabrous slitting effect and cost saving.

Standard supply: front/back knife same shaft-easy for control.

Option: front/back knife different shaft- wider control range.

WIKE-TP-Printer Unit

PRINTER

Printing phase can be controlled on the main console or each unit console.

Vacuum transfer box feeding, air volume adjustable to ensure feeding more smoothly.

Vacuum transfer box using ceramic rollers and centralized lubrication device to ensure accuracy and life span.

Printing plate, locking device on both right and left side, and quick printing plate mounting system.

Phase position adopts electromagnetic clutch locking device and automatic reset system.

Circulating ink supply control system – ink supply protection, low ink alarm, ink saving setting and quick washing.

Option (double doctor blade ink system – better printing effect).