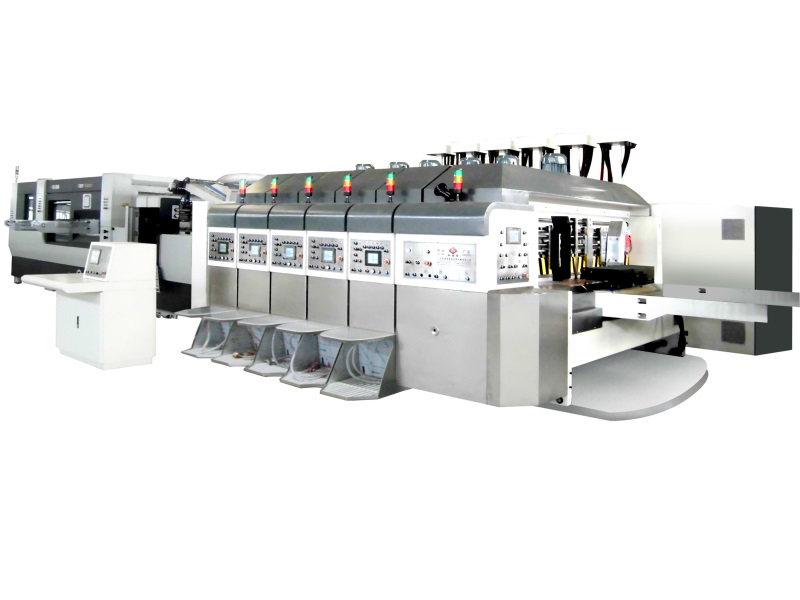

PE Automatic Platen Diecutting and creasing machine

MACHINE FEATURES

Feeder

New Maxcut lead edge feeder, more accurate and positive feeding of the corrugated board

Rear jogger at feeder to prepare for the possible future in line operation with prefeeder (optional)

Pneumatic side push guide plates (left and right sides)

Left and right side guides, individually position adjustable and register side at choice per box layout

High vacuum blower with silencer and valving system

SERVO DRIVE EXTENDED LONG FEEDING TABLE (optional)

DIE CUTTING SECTION

Crank and worm gear, toggle drive system for the lower platen

The mobile platen stroke is increased from 71mm to 95mm for handling corrugated board (especially AB Flute) smoother

Stationary high precision upper platen

Safety door and diechase safety locking system

High torque pneumatic clutch/break for positive clutch on and reliable breaking, and special air inlet system to control the air volume for smooth machine start and stop

Air cushion underneath the cutting plate for easy cutting plate in and out

Gear main drive

Overloading protection torque limit clutch

State-of-the-art 3 cam index gripper chain drive

Center line system compatible to Center Line II, makes the cutting die and stripping die centered quickly

8 high quality precision alloy gripper bars, each with 12 special hardened grippers to ensure firm grab of the sheet at high speed

Corrugated Sheet arrival and departure check photo sensor

Left and right front lay locking blocks, separating and synchronizing adjustment available

Chain guide rail use VL compound to improve abrasive resistance and seismic resistance

Self-diagnostic trouble display

Digital speed display

Automatic recycling lubrication system with oil pressure gauge and oil pressure switch

Automatic main gripper drive chain lubrication

STRIPPING SECTION

Centerline system (compatible to Centerline II) for quick stripping die set up

400mm upper stripping frame raiser enhances greatly the operation space, more operator friendly

Motorized upper frame suspending hoister

Lead edge waste removal system

DELIVERY OF DIE CUTTED BOXES

Escalator delivery fork with non-stop air cylinder for neat and positive delivery and conveyor belt delivery table to protect the corrugated die cutted boxes from scratches

Bundle delivery with pre-set counter requesting only one sheet interval in non-stop operation at 5000S/H production speed

The boxes bundle delivery table can be prepared for future connection with breaker for in line operation (to be required at order)

Full stripping with/without lead edge waste stripping convertible by one button, no tool change, more operator friendly and safe operation

Spring loaded adjustable chain tension back buffering wheel to maintain the chain tension constant and smooth gripper bar movement

Electronic corrugated die cuteed boxes batch counter

This machine is manufactured by Bobst Group.

Specifications

Maximum Sheet Size : 1620 x 1200 mm

Minimum Sheet Size : 650 x 450 mm

Maximum Cutting Size : 1600 x 1180 mm

Maximum Mechanical Speed : 5000 cycles/hour

Maximum Cutting Pressure : 400 tons

Stock Range : E, B,C,A and AB flute corrugated board (1~8.5mm)

Minimum Gripper Margin : 6-12 mm

Minimum Gripper Waste : 12 mm

(Distance from first knife to paper edge)

Cutting Rule Height : 23.8 mm

Total Power Required : 35 KW

Main Motor Power : 22 KW

Electrical Power : 380V, 50HZ, 3-phase

Air Pump Displacement : 0.7m3/min

Mobile Lower Platen Adjusting Range : ±1.5mm

Net Weight of Machine : 32 tons

Gross Weight of Machine : 39.5 tons

Machine Dimensions : 9980(L)x5670(W)x2480(H)mm (incl. Catwalk)

Optional: JB1220 Bottom flexo pinter inline flat bed die cutter

Welcome and thank you for visiting the website of Dongguan Justin Imp.& Exp. Co.,Ltd.

Welcome to the Dongguan Justin Imp.& Exp. Co.,Ltd website.We have united most leading manufacturers which specializes in manufacturing packaging machinery in China and Taiwan to supply packaging solutions to the manufacturers of all the world, especially in Europe and North America. We have cooperated with one company in Germany to market our machinery and supply immediate after service in Europe.

We at Dongguan Justin Imp.& Exp. Co.,Ltd offer a wide range of products to suit our customers in the corrugated and paperboard industries. Including new machinery, as well as the support services required for today’s market such as spare parts, technical assistance, and consultancy.

Catering for prefeeders, flexo printer slotter die-cutter inline folder gluer, bundle strappers, corrugators,casemakers, flexo and inline equipment, rotary diecutters,flatbed diecutters ,glue and stitching machines, laminating for solid corrugated and paperboard, gluing tables and printer slotters.