WIKE-BP-Die-cutter Unit

ROTARY DIE-CUTTER

Top die-cutting

Die-cutter phase can be controlled on the main console or each unit console.

Pneumatic gear gap locking device to ensure running smoothly and die cutting precisely.

Gap motorized setting and adjusting,sheet guide roll displacement motorized control, quick order change.

Rubber anvil roller automatic displacement mechanism, prolong the service life of anvil.

Quick replacement rubber anvil is imported from USA CUE.,it is easy for replacement and wear- proof.

Rubber anvil grinding mechanism which prolongs its utilization rate and reduces consume.

Precise control type speed differential compensation system to ensure die-cutting precision, and wide compensation range.

WIKE-BP-Printer Unit

Printing phase can be controlled on the main console or each unit console.

Vacuum transfer box feeding and air volume adjustable to ensure feeding more smoothly.

Vacuum transfer box using ceramic rollers and centralized lubrication device to ensure accuracy and life span.

Printing plate, locking device on both right and left side, and quick printing plate mounting system.

Phase position adopts electromagnetic clutch locking device and automatic reset system.

Circulating ink supply control system – ink supply protection, low ink alarm, ink saving setting,and quick washing.

Option (double doctor blade ink system – better printing effect).

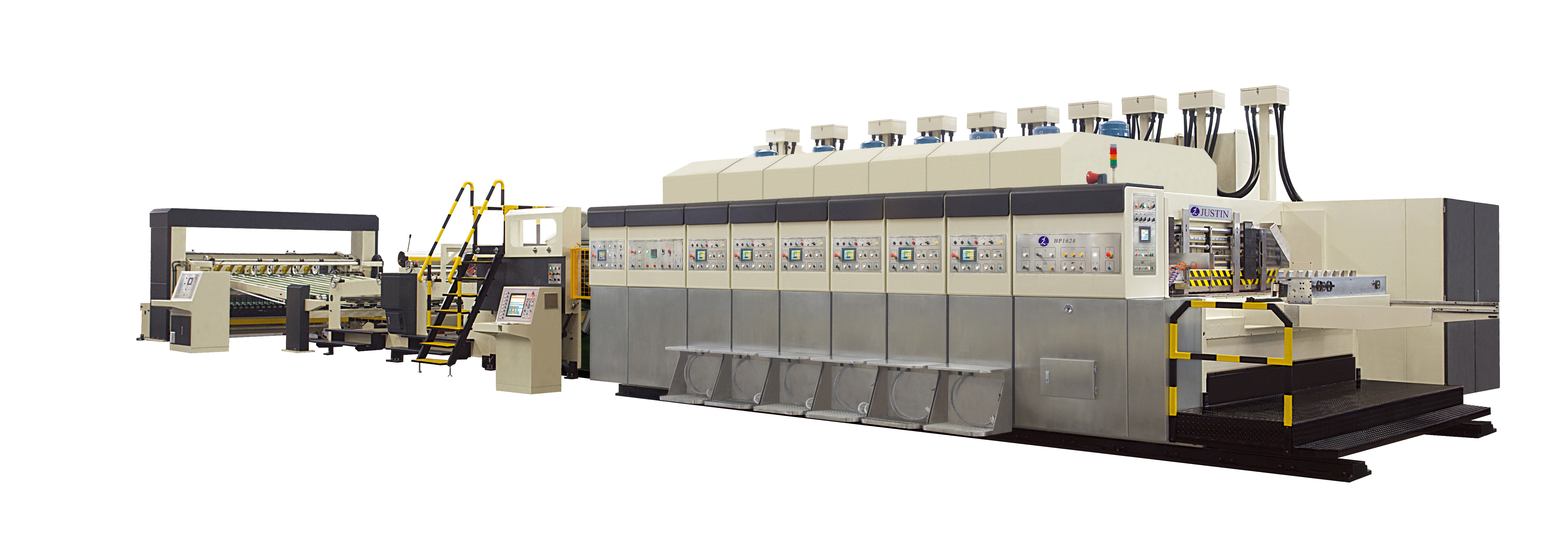

WIKE BP Bottom Flexo Printer Rotary Die Cutter

WIKE BP Vacuum Transfer Bottom Flexo rotary die cutter Machine is manufactured according to Euramerican Standard. WIKE BP adopts the best quality electrical and major parts imported from Europe,America and Japan; this achieves high efficiency and stability which create longevity and reliable safety for operators. Advanced design and integrated programs provide nice performance with minimum capital outlay and a fast return on investment.

MACHINE FEATURES

Adopting vacuum transfer bottom print and top die-cutting.

Control on the main console panel or each unit console,control fault display. Remote monitoring maintenance is supplied and trouble-shooting is more efficient.

Auto detects reset system. Quick printing plate mounting system for quicker order change.

Static charge removing device and centralized dust collection system to improved dust removal and collection.

Each unit equipped with pull string safety switch.The machine operator, working inside each unit can stop the whole machine from moving at any time.

Vacuum Transfer box adopts ceramic wheels and centralized lubrication device, so as to ensure good registration accuracy and long life span.

Driving gears are precisely grinded alloy steel with spraying type circulating lubrication system.

Electric parts, bearing, and pneumatic parts all adopt top international brand.

WIKE BP Bottom Flexo Printer Rotary Die Cutter can be with Prefeeder and Stripping Bundle Stacker to make inline.

Main Specification

| Model | WIKE BP 1200 | WIKE BP 1600 | ||||

| 2400 | 2800 | 2800 | 3200 | 3600 | ||

| Max.machine speed(sheet/min.) | 250 | 220 | 180 | 180 | 160 | |

| Max.feeding size(mm) | 1200X2400 | 1200X2800 | 1600X 2800 | 1600X3200 | 1600X3600 | |

| Skip feeding size(mm) | 1500X2400 | 1500X2800 | 2000X2800 | 2000X3200 | 2000X 3600 | |

| Max printing area(mm) | 1150X2350 | 1150X2750 | 1550X2750 | 1550X3150 | 1550X3550 | |

| Min.feeding size(mm) | 350X690 | 450 X 690 | ||||

| Printing plate thickness(mm) | 7.2 | |||||

| Min.slotting interval(mm) | Normal | 160 X 160 X 160 X 160 | ||||

| Reverse | 250 X 70 X 250 X 70 | |||||