YKC-Die-cutter unit

Die-cutter Unit

Servo drives Compensation system to get more quite precise die cutting carton.

Transverse register of die cutting roller is digitally controlled by motor.

Rubber anvil roller and die cutting roller adopted good quality steel are heated by fire and are cutted,then are grounded precisely and grinded with hard chrome. Dynamic balancing was adjusted by two sets of machines so as to reach their best.

Equipping with automatic rectification waste cleaning device.

YKC-Slotter unit

Slotter Unit(SINGLE SHAFT)

Equipped with self-locking, pre-scoring and quick adjusting device guarantees long-term precision between shaft and wheel and avoid damaging cardboard.

Upper scoring wheel coated with polyurethane to avoid damaging cardboard.

Left and right synchronous motorized shaft to make upper and down scoring wheels, upper and down slotting knife, and guiding wheel adjust synchronously.

Self-lubricant wearable block makes scoring wheel,slotting wheel,and guiding wheel move right and improve durability.

Thickness of the alloy steel slotting knife is7mm. And the hackle blade can prolong its using life and keep perfect slotting effect.

YKC-Printer unit

Printer Unit

Printing phase and axial motion are controlled by PLC. Automatic zero setting and reset.

Anilox roller works with feeding unit synchronously up and down automatically.

Pulling feed roller with self-locking and quick adjusting function has easy operation and can avoid damaging roller.

Printing phase equips with electromagnetic clutch mechanism. When the unit is separated,it can fix position of the gear so as to keep the primary printing position.

Printer unit equips with motorized foot switch so as to hang and adjust forme quickly and clear.

Automatic washing device can save inks effectively (0.3~0.5kg each time at each printer)

Rubber roll with Steel Anilox roll ink supply system.

Domestic Ceramic Anilox Rolls(200-280Lpi) is optional.

Single or Dual doctor blade ink system is optional.

YKC-Feeder unit

Feeder Unit

Servo motor drives lead edge feeder so as to get more precise and more stable feeding.

Automatic feeding mechanism works with ink roller synchronously to guarantee printing quality and to reduce waste as well.

The left, right and rear baffle are regulated by motor. Manual or automatic cardboard trimming and working frequency can be set freely.

Equipped with upper dust suck removing mechanism can regulate volume of wind according to your requirements.

Adopting two pairs of feeding roller and upper rubber rollers with hard surface and soft inside to guarantee good extensibility and have good wear-resisting.

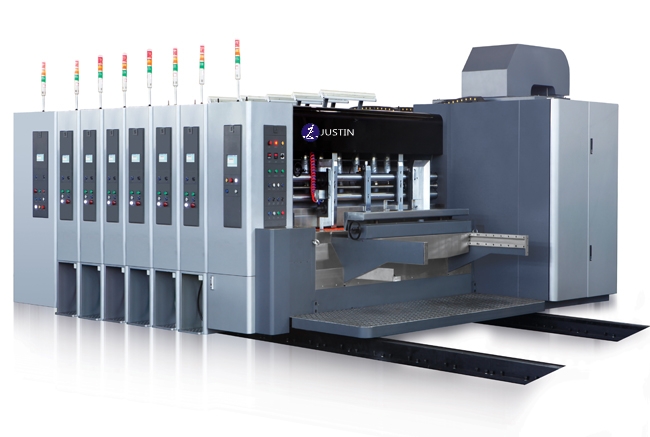

YKC-Machine features

YKC machine is a classic flexo printer slotter die-cutter, which reflects state-of-art design and is very practical. It is designed for high performance, reliability, operator’s safety and user-friendly controls to produce top quality cartons.Vacuum transfer ST Flexo printer slotter is available.

WHOLE MACHINE INTRODUCTION

The machine is controlled by PLC and the phase is regulated by frequency converter.

Servo drives lead edge feeder to get more precise and more stable feeding.

Servo drives Compensation system to get more quite precise die cutting carton.

Being able to store 9999 orders.

Automatic washing device can save inks effectively (0.3~0.5kg each time at each printer).

Driving gears adopt 20CrMnTi alloy steel. The gears are heated especially and then precisely grinded and reach 6 grade precision and HRC 58-62 degree.

All drives shafts are made of high-quality steel, chrome plated, and surface ground.

Pulling feed roller with self-locking and quick adjusting function has easy operation and can avoid damaging roller.

Adopting free loop bound to reduce abrasion and print accurately.

All units of the machine can be separated automatically or manually and an audible alarm sounds during the opening and closing for safe operation.

Gap adjust adopts self-lock adjusting device,and it is easy for operation.

The lubricating system adopts spraying anti-squirt device and automatic circulating lubrication with anti-leakage oil mechanism.

Main Specifications:

|

Model |

YKC-1000 |

YKC-1200 |

YKC-1400 |

YKC-1600 |

||||||

|

1800 |

2200 |

2500 |

2800 |

2500 |

2800 |

2500 |

2800 |

|||

|

Max. feeding size(mm) |

1760*970 |

2160*970 |

2500*1170 |

2800*1170 |

2500*1370 |

2800*1370 |

2500*1570 |

2800*1570 |

||

|

Min. feeding size(mm) |

650*280 |

650*280 |

650*350 |

650*350 |

650*380 |

650*380 |

700*400 |

700*400 |

||

|

Skipping feeding(mm) |

1760*1170 |

2160*1170 |

2500*1370 |

2800*1370 |

2500*1570 |

2800*1570 |

2500*1770 |

2800*1770 |

||

|

Max.printing area(mm) |

1750*950 |

2150*950 |

2450*1150 |

2750*1150 |

2450*1350 |

2750*1350 |

2450*1550 |

2750*1550 |

||

|

Standard printing plate thickness(mm) |

7.2 |

7.2 |

7.2 |

7.2 |

||||||

|

Min.slotting space(mm) |

Normal | 120*120*120*120 | 140*140*140*140 | 150*150*150*150 | 150*150*150*150 | |||||

|

Reverse |

190*50*190*50 |

250*80*250*80 |

250*80*250*80 |

250*80*250*80 |

||||||

| Effective feeding range(mm) |

2.5-10 |

2.5-10 |

2.5-10 |

2.5-10 |

||||||

|

Max. slotting depth(mm) |

300 |

300 |

350 |

350 |

350 |

350 |

350 |

350 |

||

|

Max. speed(sheet/min) |

200 |

200 |

170 |

170 |

150 |

150 |

130 |

130 |

||